How to Modify Sccy Cpx1 9mm to Fix Failure to Feed

One of my buddies loaned his Ruger LCR to a co-worker for off-duty carry. The co-worker is a newer cop and she was short on funds after having a baby. It got me thinking that not everyone in the squad room can afford an expensive back-up piece. Introducing: SCCY Industries.

SCCY Industries, LLC (pronounced "Sky") makes handguns in Daytona Beach, Florida. After handling their Generation 2 CPX-1 and CPX-2's at SHOT Show, I was impressed with the design and quality control of their 9mm polymer pistols. Fit and finish was above average, especially if you factored in the MSRP: $319.00 for the CPX-1 and $299.00 for the CPX-2! It elicited a "Wow!" and a "Hmmmm…" at the same time.

Since SCCY did not have a range booth at Media Day, I would have to find another way to road test one of their pistols. After a few phone calls, I got one shipped to my local gun store. When I opened the SCCY box, I was shocked. Not only was the little 9mm pistol nestled in there, the CPX-2 came with two magazines, two finger extension mag bases, and two flat mag bases. There was also a very nice spring loaded trigger lock and keys.

Mr. Roebuck had been following firearms marketing trends and legislation since 1998. He felt he could produce a high quality firearm that was manufactured in a cost effective manner, resulting in a precision-made pistol sold at a low price point to the consumer. In addition, SCCY pistols carry a lifetime warranty that stays with the gun, not the owner.

Generation 2 CPX Features:

• Barrel: machined from bar stock with 7 lands and grooves having a 16‐1 right hand twist.

• Receiver: 7075‐T6 aircraft grade heat treated aluminum alloy, machined from bar stock.

• Grip/Frame: Made from Zytel polymer, with ergonomic finger grooves and an integral "RE-COIL CUSHION" on the back‐strap.

• Recoil Spring System: all steel, fully encapsulated for ease of disassembly and reassembly.

• Slide Lock/Release: steel with a Zytel over molded polymer extension for ease of operation.

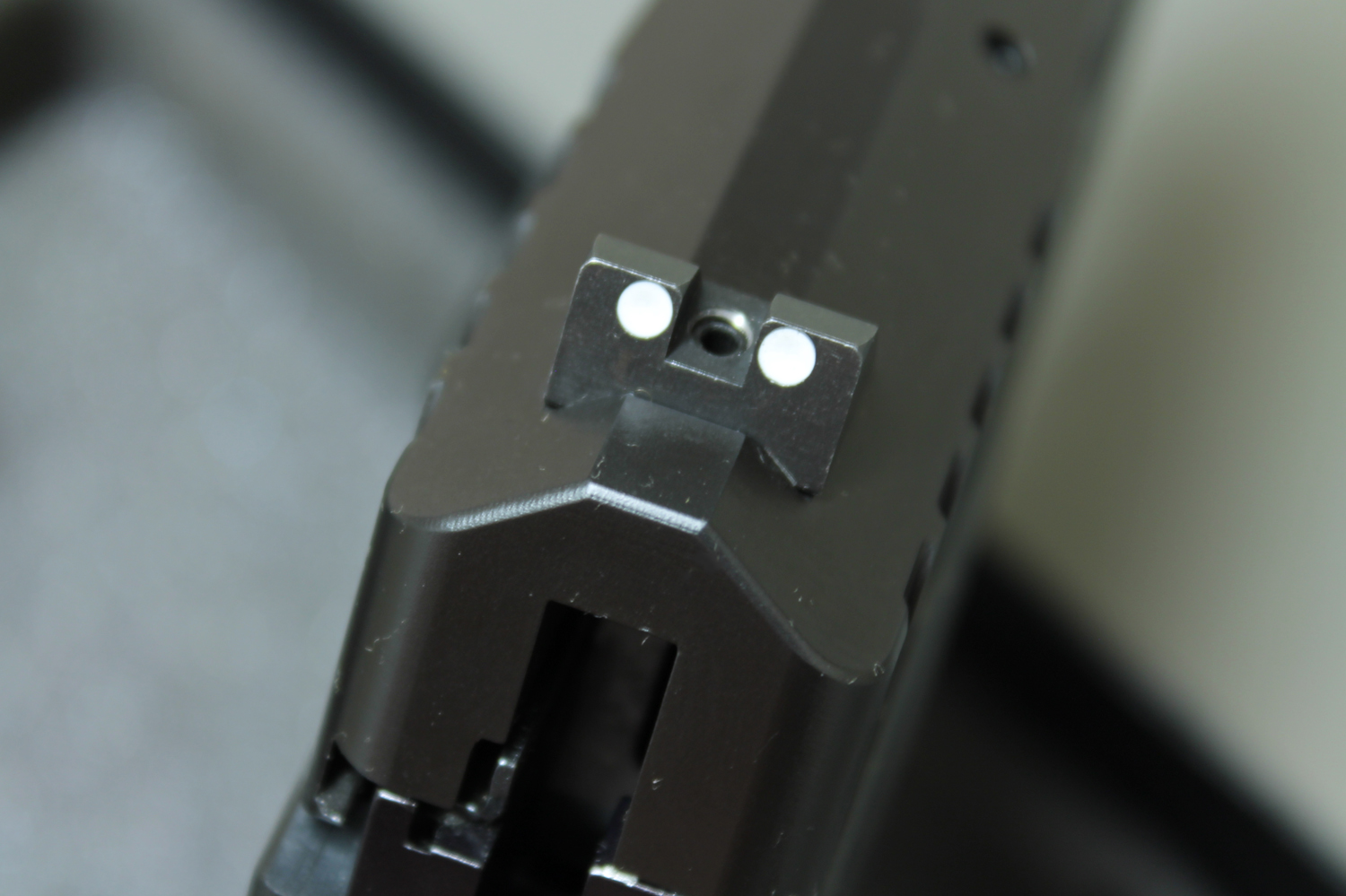

• 3 dot sight system: steel rear sight, adjustable for windage only with locking screw.

• Hammer firing system: double action only, internal hammer with inertial firing pin to prevent accidental discharge if dropped.

• Manual Guarded Safety: CPX‐1 only. Newly designed with a guard molded into the frame. CPX-2 has NO manual safety.

• Double action trigger: specifically designed for shooter comfort and accuracy by designing the system to have a smooth effortless, consistent 9 pound trigger pull.

• Magazine: included with (2) double stack, 10 round capacity magazines with finger extension base installed and 2 flat magazine bases included.

• Trigger Guard Lock: custom designed to properly fit and be child resistant. Includes 2 keys.

After taking delivery of the CPX, I made it to the range several weeks later. (Hey, I get busy, too.) I had brought along the bag of what I like to call "shitty 9mm ammo." I don't even know what some of it was. There was a mixture of hollowpoints, hardball, and frangible bullets from various manufacturers. I know some of it was at least 10-15 years old. I seem to add to the bag every so often after range trips or when given castoff junk ammo.

Dry-firing downrange, I rolled the serrated trigger back several times. SCCY says the trigger is set for about 9 lbs. of pull. Seemed so. It had a longish trigger pull that was pretty consistent in feel until the sear released the hammer. Hammer—can you say second strike capability?

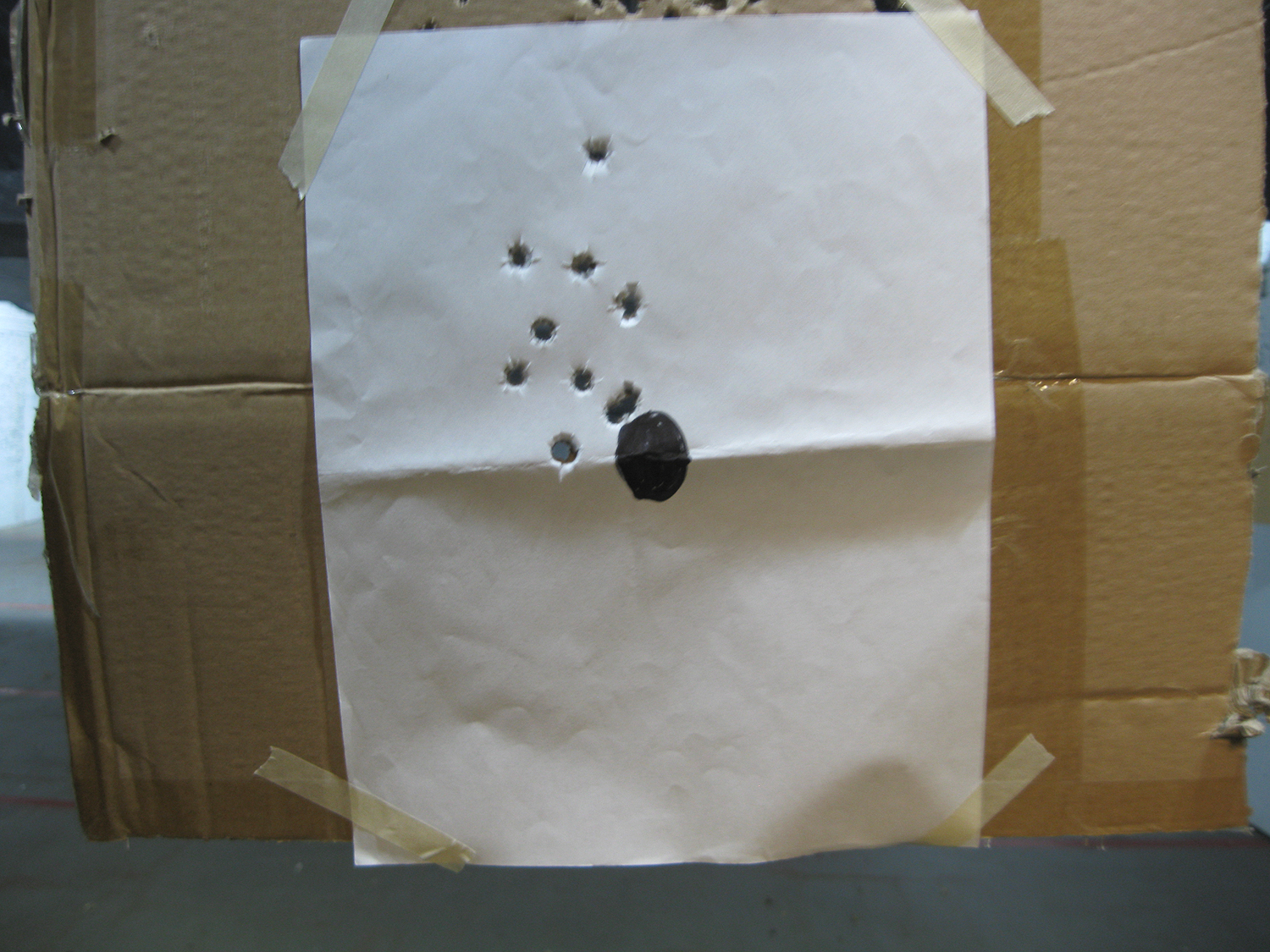

Now, I blindly loaded mixed mags of bullets. Every time I pulled the trigger, the gun fired, a casing was thrown from the gun, and a new round was chambered. Several hundred rounds later, the CPX-2 was still batting a thousand. I was back to "Wow!" and had left "Hmmm…" by the wayside. This gun impressed me. And kudos to the shitty ammo.

The backstrap of the pistol has what SCCY calls a Re-Coil Cushion. It consists of five oblong holes on each side of the backstrap. Make no mistake, the Zytel handle of the gun is rigid. A push on the area around the holes shows the polymer material yields very, very slightly because of its thinning. It may lead to some lessening of the perceived snap in the hand.

Under fire, I found the shape of the grip and integral finger grooves comfortable in the hand. The slide release is easy to find with the thumb, but hard to activate accidentally. My CPX-2 model does not have the manual safety selector, nor did I want it to have one. "Well, this is my safety, sir." Hoot, Blackhawk Down…

Jason, the Armorer/Service Manager at SCCY, said that the Generation 2 CPX's are cleared for a limited use of +P rated 9mm ammunition. However, the caveat is that their use will accelerate the wear and tear on the gun. Personally, I am fine with the lethality of standard pressure 9mm with a good bullet.

For concealed carry, the 15 oz. unloaded weight and melted characteristics of the exterior package make it ideal. And you get 11 rounds of 9mm, where some similar guns give you 7 shots for the same basic weight and size.

Randall

matthiesthandsoll.blogspot.com

Source: http://thinblueflorida.com/?p=5016

0 Response to "How to Modify Sccy Cpx1 9mm to Fix Failure to Feed"

Post a Comment